1004,West-CBD,No.139 Binhe Rd,Futian District,Shenzhen, China Post Code:518048

1004,West-CBD,No.139 Binhe Rd,Futian District,Shenzhen, China Post Code:518048

+86-18682200597

+86-18682200597

sales@szhaiwang.com

sales@szhaiwang.com

1004,West-CBD,No.139 Binhe Rd,Futian District,Shenzhen, China Post Code:518048

1004,West-CBD,No.139 Binhe Rd,Futian District,Shenzhen, China Post Code:518048

+86-18682200597

+86-18682200597

sales@szhaiwang.com

sales@szhaiwang.com

source:Industry News release time:2023-07-19 Hits: Popular:Infrared sensing module

Raw material testing

All raw materials must be tested upon receipt to confirm whether their physical and electrical properties are acceptable. A unique ID # has been assigned and used for batch traceability.

Mixing of raw materials

The manufacturing of NTC thermistors begins with the precise mixing of raw materials into an organic adhesive solution. These raw materials are powdered Transition metal oxides, such as manganese, nickel, cobalt and copper oxides. Other stabilizers are also added to the mixture. Mix oxides and adhesives using a wet process called ball milling. During the ball milling process, mix the materials and reduce the particle size of the oxide powder. The completed uniform mixture has the consistency of a thick slurry. The exact composition of various metal oxides and stabilizers determines the resistance temperature characteristics and resistivity of fired ceramic components.

Magnetic tape casting

Use scraper technology to distribute the "slurry" on the moving plastic carrier sheet. By adjusting the height of the scraper above the plastic carrier, the speed of the carrier, and by adjusting the viscosity of the slurry, the exact material thickness can be controlled. When the casting material is dried on a flat casting strip through a long tunnel furnace at high temperature, it is dried. The obtained "green" tape has ductility and is easy to shape. Then conduct quality inspection and analysis on the tape. The casting thickness range of this thermistor strip is wide, from 0.001 "to over 0.100", depending on the specific component specifications.

Wafer formation

Now the casting strip can be formed into a chip. When thin material is needed, simply cut the tape into small squares. For thicker chips, cut the tape into squares and stack them one on top of the other. Then, these stacked chips are laminated together. This enables us to produce wafers of almost any thickness. Then, the wafer undergoes additional quality testing to ensure high uniformity and quality. Subsequently, the chip undergoes a binder burn cycle. This process removes most of the organic adhesive from the chip. Maintain precise time/temperature control during the adhesive burn out cycle to prevent adverse physical stress on the thermistor chip.

Read recommendations:

Introduction to long life NTC thermist resistance.Ultrasonic module price

Popular Recommended Products

Φ4mm size

2021-11-27PIR Lens 8011

2021-12-09HW-11802400 Imaging Fresnel lens

2024-04-11PIR300B Analog sensor

2021-12-09PND103F3950FTR306 NTC Thermistor 10K 1% 3950

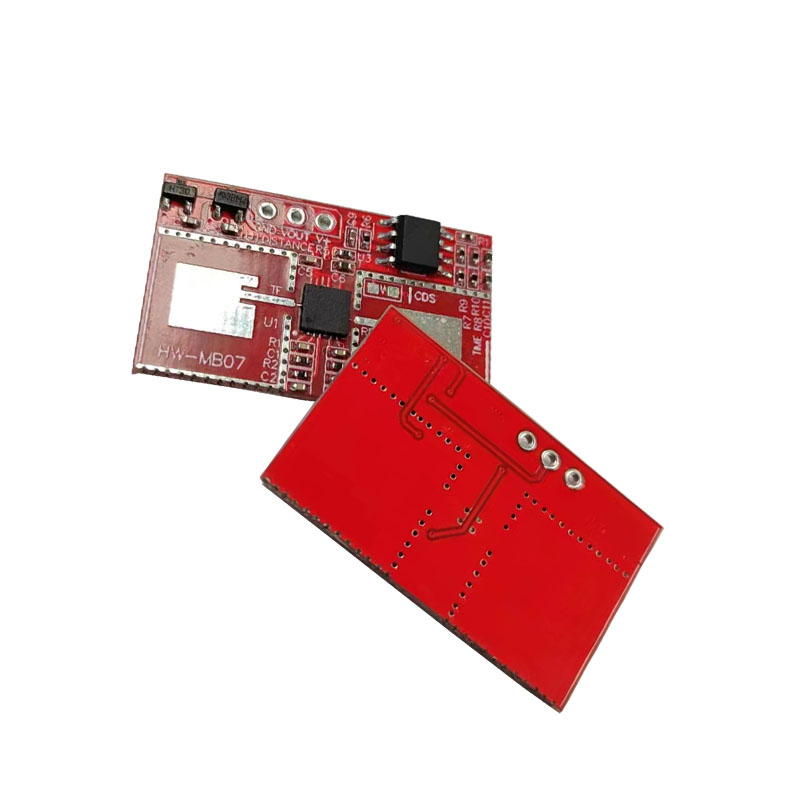

2021-11-27HW-XC901 microwave sensor module

2021-12-07Digital PIR Sensing Controller 3312-3s

2024-03-22PIR Lens SIR650

2021-12-09PND103F3950FTR304 NTC Thermistor

2021-11-278308-A PIR lens

2021-12-178038 PIR lens

2021-12-17The Application of NTC Thermistors in Far Infrared Heaters.Motion sensing module

2023-08-23How do I fake circular buffers in FIR software?

2022-11-01Resistance tolerance of NTC and corresponding temperature tolerance.SMD PIR IC Manufacturing

2022-06-25FIR low nitrogen combustion technology

2022-10-24NTC glass sealed thermistor suitable for use in narrow spaces

2023-09-11NTC for BMS

2023-07-13Discussion on waterproof and moisture-proof temperature sensors.Human Body Motion Sensor

2023-08-11LED light and NTC thermistor resistance.CDS sensor manufacture

2023-03-09Analysis of the characteristics of photoelectric switch of radio frequency sensor

2022-01-21Temperature NTC temperature measuring element used in smart wear.5.8G Frequency microwave sensor mod

2022-08-17

szhaiwang4@hotmail.com

+86-18682200597

sales@szhaiwang.com