1004,West-CBD,No.139 Binhe Rd,Futian District,Shenzhen, China Post Code:518048

1004,West-CBD,No.139 Binhe Rd,Futian District,Shenzhen, China Post Code:518048

+86-18682200597

+86-18682200597

sales@szhaiwang.com

sales@szhaiwang.com

1004,West-CBD,No.139 Binhe Rd,Futian District,Shenzhen, China Post Code:518048

1004,West-CBD,No.139 Binhe Rd,Futian District,Shenzhen, China Post Code:518048

+86-18682200597

+86-18682200597

sales@szhaiwang.com

sales@szhaiwang.com

source:Industry News release time:2023-06-01 Hits: Popular:Infrared sensing module

Positive temperature coefficient (PTC) refers to the phenomenon or material of a thermistor with a rapid increase in resistance at a certain temperature and a positive temperature coefficient, which can be specifically used as a constant temperature sensor. This material is a sintered body mainly composed of BaTiO3, SrTiO3, or PbTiO3, in which trace amounts of Nb, Ta, Bi, Sb, Y, La and other oxides are added for atomic valence control to make it semiconductive, This semiconducting material such as BaTiO3 is often referred to as semi conductive (bulk) ceramics; At the same time, the oxides of Mn, Fe, Cu, Cr and other additives that increase their positive resistance temperature coefficient are also added, and platinum titanate and its solid solution are semiconducting by general ceramic process forming and high temperature sintering, so as to obtain positive thermistor materials. The temperature coefficient and Curie point temperature vary with the composition and sintering conditions (especially the cooling temperature).

Barium titanate crystal belongs to perovskite type structure and is a ferroelectric material, while pure barium titanate is an insulating material. After adding trace rare earth elements into barium titanate material, after proper heat treatment, the resistivity increases several orders of magnitude near the Curie temperature, resulting in PTC effect, which is related to the ferroelectricity of BaTiO3 crystal and the phase transformation of the material near the Curie temperature. Barium titanate semiconductive ceramics are a polycrystalline material with intergranular interfaces between grains. When the semi conductive ceramic reaches a specific temperature or voltage, the crystal grain boundaries change, resulting in a sharp change in resistance.

The PTC effect of barium titanate semiconductive ceramics is caused by grain boundaries (grain boundaries). For conductive electrons, the intergranular interface acts as a potential barrier. When the temperature is low, due to the electric field inside barium titanate, electrons are easily able to cross the potential barrier, resulting in a smaller resistance value. When the temperature rises near the Curie temperature (i.e. critical temperature), the internal electric field is destroyed and cannot help conductive electrons cross the potential barrier. This is equivalent to an increase in potential barrier and a sudden increase in resistance, resulting in the PTC effect. The physical models of PTC effect of BaTiO3 semiconducting ceramics include the Haiwang surface barrier model, Daniels' barium vacancy model and superimposed barrier model, which explain PTC effect reasonably from different aspects.

The experiment shows that within the working temperature range, the resistance temperature characteristics of PTC thermistors can be approximated by the experimental formula:

R (T)=R (T0) * exp (Bp (T-T0))

In the formula, R (T) and R (T0) represent the resistance values at temperatures of T and T0, and Bp is the material constant of the material.

The PTC effect originates from the properties of precipitates at and between the grain boundaries of ceramics, and varies significantly with the type, concentration, sintering conditions, and other impurities. Recently, among the practical thermistors, there are silicon temperature sensitive components that utilize silicon wafers. This is a small and high-precision PTC thermistor, composed of n-type silicon. The electron scattering generated by impurities in it increases with temperature, resulting in an increase in resistance.

PTC thermistors emerged in 1950, followed by the emergence of PTC thermistors using barium titanate as the main material in 1954. PTC thermistors can be used for temperature measurement and control in industry, as well as temperature detection and regulation in certain parts of automobiles. They are also widely used in civilian equipment, such as controlling the water temperature of instant water heaters, air conditioners and cold storage temperatures, and using their own heating for gas analysis and wind turbines. Below is an example of the application of heating and overheating protection for appliances such as heaters, motors, transformers, and high-power transistors.

PTC thermistors not only serve as heating elements, but also serve as "switches", which have three functions: sensitive elements, heaters, and switches. They are called "thermal switches". After the current passes through the component, it causes a temperature increase, that is, an increase in the temperature of the heating element. When the temperature exceeds the Curie point, the resistance increases, limiting the increase in current. As a result, the decrease in current leads to a decrease in the temperature of the component. The decrease in resistance value also increases the circuit current, causing the temperature of the component to rise repeatedly. Therefore, it has the function of keeping the temperature within a specific range and also plays a switching role. Utilizing this temperature resistance characteristic to make a heating source, it can be used as a heating element, such as a heater, electric soldering iron, wardrobe dryer, air conditioner, etc. It can also provide overheating protection for electrical appliances.

Read recommendations:

NTC thermistors for small ceramic heaters

Building monitoring devices and NTC temperature sensors.Human Body Temperature Monitoring Sensor

Popular Recommended Products

PIR Lens 8066

2021-12-09PND103F3950FTR305 NTC Thermistor

2021-11-27HW806

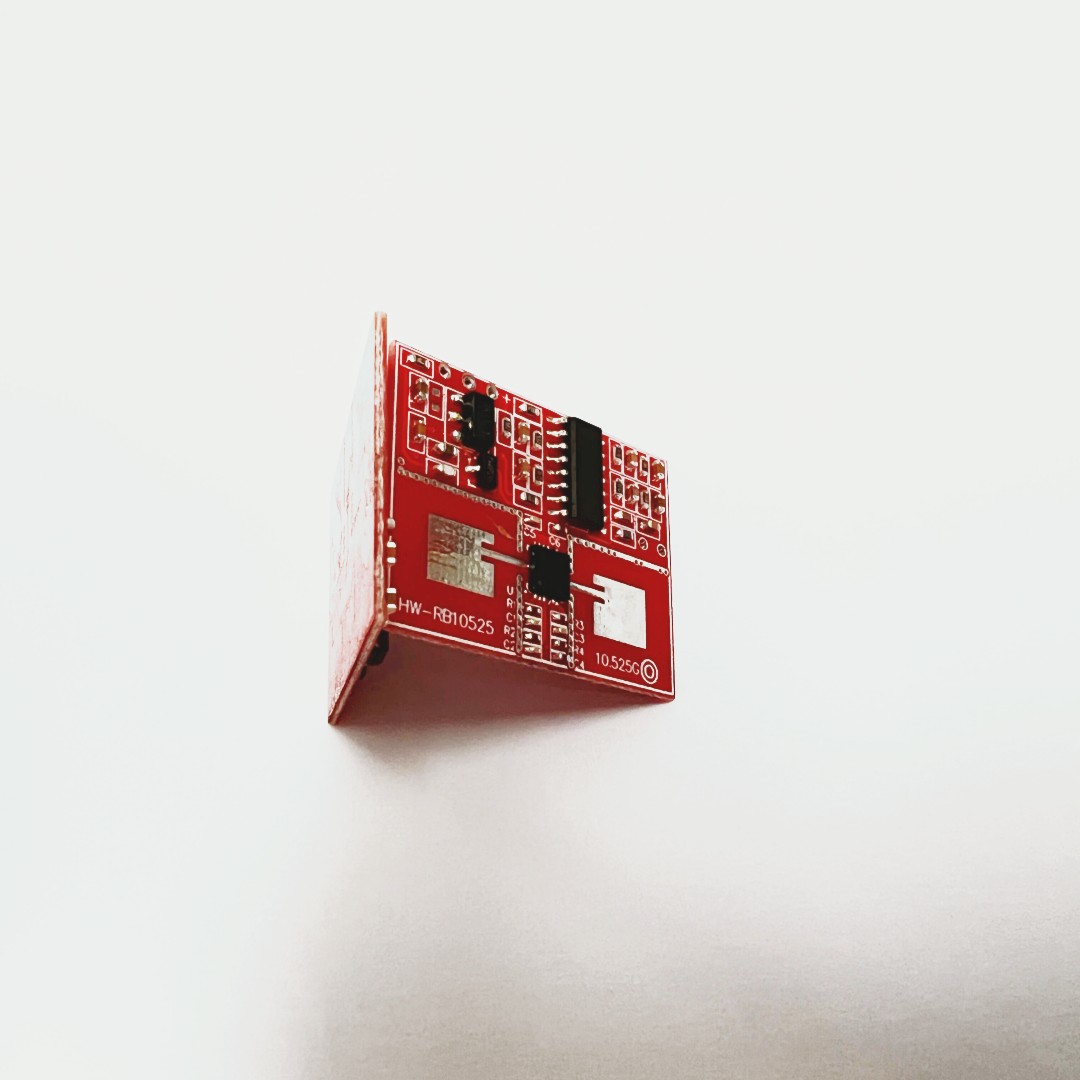

2021-11-27HW-MS03 microwave sensor module

2021-12-07Wide-Angle Fresnel Lens

2021-11-27PIR Lens 8019

2021-12-09PND103F3950FTR306 NTC Thermistor 10K 1% 3950

2021-11-27PIR Lens 8003-2

2021-12-09PIR Lens 8005

2021-12-09PIR Lens 7809

2021-12-09HW8004 Night light microwave sensor module,PIR sensor module

2021-12-07How to properly install the ntc temperature protector.Human Body Temperature Monitoring Sensor

2022-06-02Progress in Measuring NTC Ceramic Thermistor Technology

2023-07-15NTC Solves ODN Management Challenges.Human Body Temperature Monitoring Sensor

2023-07-06How to choose NTC thermistor.motion detector Vendor

2022-06-16NTC thermistor for disinfection cabinet.Fresnel Lens manufacture

2022-09-24Technical requirements for MF52 series NTC thermistor

2023-02-21Features of NTC thermistor of PVC # double splice line

2022-12-14NTC thermistor temperature sensor.Infrared sensing module Manufacturing

2022-07-08Features of FIR filter

2022-10-19NTC temperature sensor for IoT fire warning system.Microwave Sensor Module

2023-09-12

szhaiwang4@hotmail.com

+86-18682200597

sales@szhaiwang.com