1004,West-CBD,No.139 Binhe Rd,Futian District,Shenzhen, China Post Code:518048

1004,West-CBD,No.139 Binhe Rd,Futian District,Shenzhen, China Post Code:518048

+86-18682200597

+86-18682200597

sales@szhaiwang.com

sales@szhaiwang.com

1004,West-CBD,No.139 Binhe Rd,Futian District,Shenzhen, China Post Code:518048

1004,West-CBD,No.139 Binhe Rd,Futian District,Shenzhen, China Post Code:518048

+86-18682200597

+86-18682200597

sales@szhaiwang.com

sales@szhaiwang.com

source:Industry News release time:2023-07-15 Hits: Popular:Infrared sensing module

The excellent porcelain precise measurement technology developed and designed recently is specialized in the production and processing of technical high reliability Electroceramics thermistor raw materials. This new material has been introduced into the selection and application of a series of high-performance NTC thermistor components and detector components.

The application of the NTC thermistor controller's resistance controller to two key elements is particularly important for important customers. The controller must first display information in a specific way and should present the same electrical equipment again, in order to present the same electrical equipment characteristics during the first production and manufacturing of the entire service life. Based on this important delivery effect, professional staff of precision measurement technology have invested many high reliability Electroceramics raw material projects in engineering project resources, which can be used for most scientific research, development, design and application around the world

The unique technology is used to produce porcelain with uniform particle size distribution in the whole process of high density manufacturing. The most important aspect of powder production and processing is to improve the particle size distribution and bulk density by adjusting the particles. In addition, by adjusting the adhesive system software and using appropriate organic chemical preservatives, particles that enhance deformation can be carefully selected.

The output power of the spray dryer is tamped with various technologies, which shows a suitable geometric figure for the production of ntc chips. Strict application of the best production technology in the final stage of porcelain production and processing. The application of high-pressure porcelain throughout the entire production process improves the physical properties of porcelain within a certain period of time. Accurate control of temperature, working pressure, and production processing time is required to achieve mechanical equipment and electrical performance regulations. The entire process of high density allows for the collapse of voids under high pressure. The gap surface is combined with a reasonable removal of porosity, achieving nearly 100% of the basic theoretical relative density.

1. High density of 100% basic theory of electric porcelain with relative density.

2. Remove the internal porosity of porcelain.

3. Improved the process performance of electrical grade ceramic components.

4. The high resistor further improves the electrical performance of d.

5. The widespread improvement in repeatability and usage performance.

6. Fine grain structure of excellent Electroceramics raw materials.

Read recommendations:

What makes FIR filter digital quality better?

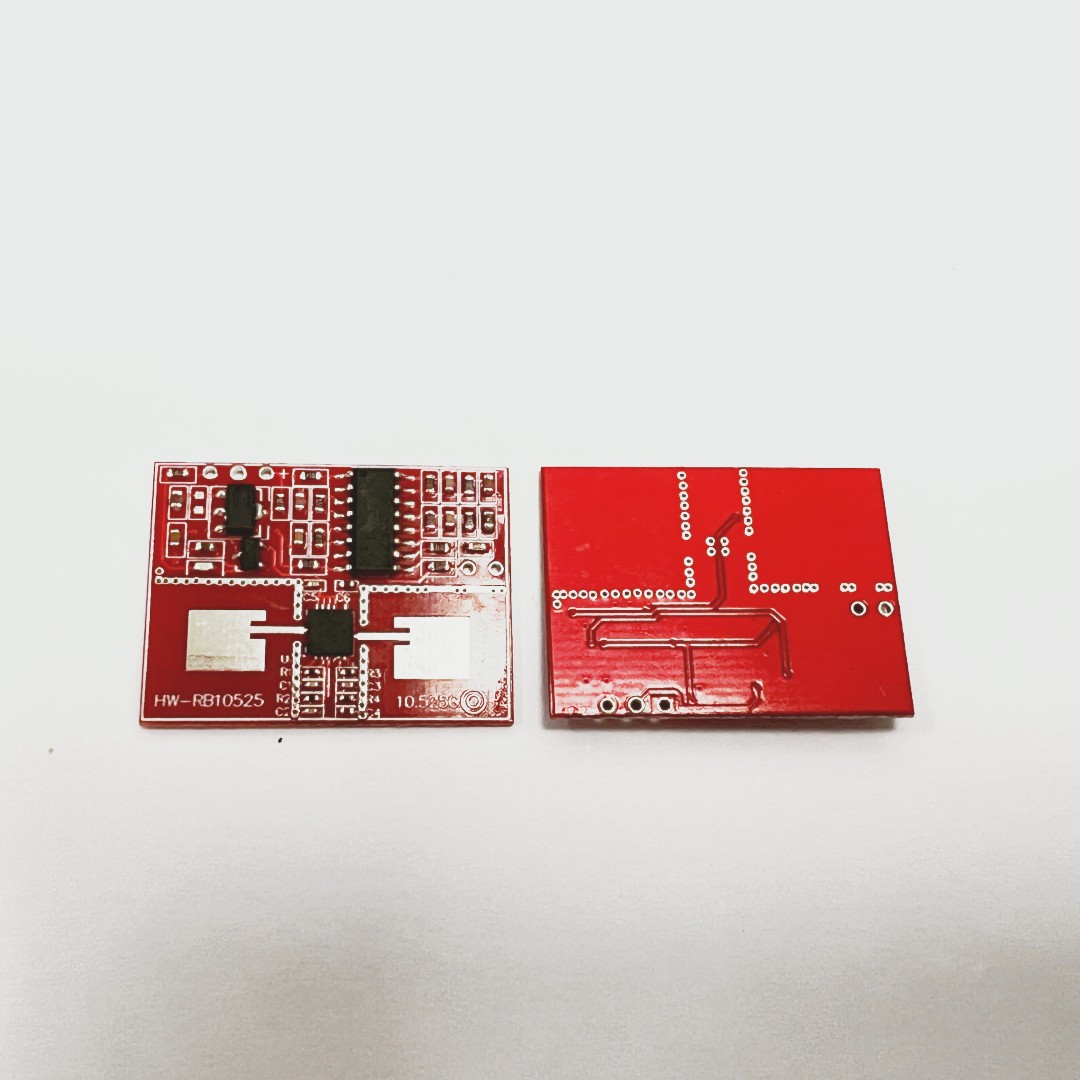

NTC Negative Temperature Coefficient Thermistor.5.8G Frequency microwave sensor module

Popular Recommended Products

TP-L80

2021-11-27RX-50

2021-12-09PIR Lens 8005

2021-12-09PND103F3950FTR319

2021-11-27PIR Lens 8120-4

2021-12-09square lens

2021-11-27PIR Lens 8120-3

2021-12-09HW8004 Night light microwave sensor module,PIR sensor module

2021-12-07HW808

2021-11-27HW-M21 microwave sensor module

2021-12-07PIR Lens 8005-1

2021-12-09NTC Temperature Control Probes for Wall Breakers.Traffic lens Processing

2022-09-24NTC temperature sensor for power well

2022-08-25DARPA has developed near-zero power RF chips and sensors.Body Movement Sensor Factory

2022-01-07Precautions for installation and use of human body sensor

2022-11-07What should I pay attention to when buying NTC thermistor?Radar Sensor Switch

2023-06-06How to use radio frequency ranging sensor to monitor the water level of manhole.Microwave Radar Sens

2022-07-23What is surface mount technology (SMT)?

2021-11-27Understanding wireless sensors

2022-01-17Introduction to body sensor detection principle

2022-11-21Features of FIR filter

2022-10-19

szhaiwang4@hotmail.com

+86-18682200597

sales@szhaiwang.com