1004,West-CBD,No.139 Binhe Rd,Futian District,Shenzhen, China Post Code:518048

1004,West-CBD,No.139 Binhe Rd,Futian District,Shenzhen, China Post Code:518048

+86-18682200597

+86-18682200597

sales@szhaiwang.com

sales@szhaiwang.com

1004,West-CBD,No.139 Binhe Rd,Futian District,Shenzhen, China Post Code:518048

1004,West-CBD,No.139 Binhe Rd,Futian District,Shenzhen, China Post Code:518048

+86-18682200597

+86-18682200597

sales@szhaiwang.com

sales@szhaiwang.com

source:Industry News release time:2022-07-13 Hits: Popular:Infrared sensing module

In the traditional food baking process, the baking temperature and time are mainly controlled manually, and the heat is uncontrollable. Either the heat is too high, the food is too warm, and the food is mushy; or the temperature is not enough, and the time is too long. , affecting the taste; better control of temperature and humidity has become the most important thing in the production of baked goods.

We know that the NTC temperature sensor is a negative temperature coefficient thermistor. It is made of transition metal oxide as the main raw material and made of advanced ceramic technology. These metal oxide materials all have semiconducting properties because they are completely similar to semiconductor materials such as germanium and silicon in electrical conductivity. When the temperature is low, the number of carriers (electrons and holes) of these oxide materials is small, so its resistance value is higher; as the temperature increases, the number of carriers increases, so the resistance value decreases. The variation range of NTC thermistor at room temperature is 100~1000000 ohms, and the temperature coefficient is -2%~-6.5%. Using these characteristics, NTC temperature sensors can be widely used in temperature measurement, temperature compensation, suppression of surge current and other occasions.

In the selection of food-grade NTC temperature sensors, the following aspects need to be considered:

First, clarify the product application function

1. Temperature measurement

2. Temperature compensation

3. Inrush current suppression

two. Clarify the working temperature range of the product - correspondingly select the corresponding material and packaging form

1. Epoxy resin encapsulation: moisture resistance, high dielectric strength, working temperature -40℃~+125℃.

2. Silicone resin encapsulation: high dielectric strength, working temperature -40℃~+200℃, and average moisture resistance.

3. Glass encapsulation package: moisture resistance, high dielectric strength, high temperature resistance, working temperature -40℃~+350℃.

4. Bare metal wire: Since there is no outer insulation, the operating temperature depends on the temperature of the packaging material.

5. PVC electronic wire: Working temperature -40℃~+(90-110)℃.

6. Teflon electronic wire: working temperature -40℃~+220℃.

7. Silicone electronic wire: Working temperature -40℃~+250℃.

8. High temperature fluoroplastic wire: Working temperature -40℃~+150℃.

three. Determine the resistance value (zero power resistance value) RT and material constant - B value at the temperature required for the design

(1) Zero-power resistance value RT (Ω)

RT circuit design specifies the required resistance value at temperature T.

A zero-power resistance value refers to a resistance value measured with a measurement power that causes a change in resistance value to be negligible relative to the total measurement error.

(2) Material constant - B value

Material constant (thermal index) B value (unit: Kelvin temperature).

It can be roughly understood as the slope of the NTC thermistor/temperature sensor as the temperature increases.

Determining the B value determines the resistance-temperature curve.

Four. Defining the required response speed - thermal time constant τ

In layman's terms, the thermal time constant τ is the sensitivity of the NTC thermistor/temperature sensor to sense temperature.

Under the condition of zero power, when the temperature suddenly changes, the time required for the temperature of the thermistor body to change by 63.2% of the temperature difference between the beginning and the end.

Choose a suitable τ: The τ value directly reflects the response speed of the NTC to measure the temperature, but the smaller the better, the determination of the τa value requires comparison and trade-off. Because the τ value is related to its package size, the smaller the package size of the NTC, the smaller the τa value and the lower the mechanical strength; the larger the package size, the larger the τa value and the higher the mechanical strength.

five. Understanding Dissipation Coefficient δ

Read recommendations:

How to choose NTC temperature sensor.PPTC Thermistor Vendor

Three important roles of negative temperature coefficient thermistor NTC.SMD PIR IC manufacture

Popular Recommended Products

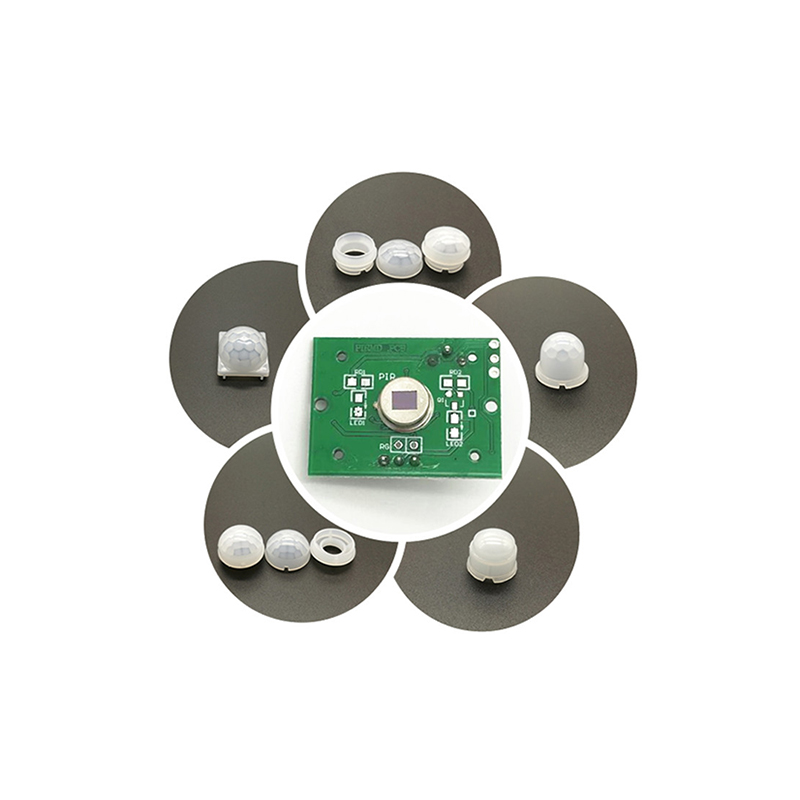

PIR Lens 8801-2

2021-12-09P918H Digital sensor

2021-11-27PIR Lens 7803

2021-12-09PIR Lens 8011

2021-12-09PIR Lens 8002-3

2021-12-09HW-F1000-1 Fresnel Solar Lens

2021-11-27PND103F3950FTU101

2021-11-27HW-11802400 Imaging Fresnel lens

2024-04-11PND103F3950FTR325

2021-11-27PIR Lens 8120-3

2021-12-09PIR Lens 7709-2

2021-12-09MF52A epoxy NTC resistance characteristics

2023-02-16NTC 10K B value 3950 enamelled wire thermistor

2022-12-06Electronic thermometer NTC thermistor resistance.Human Body Infrared Temperature Sensor Vendor

2023-04-12HNB electronic cigarette and NTC temperature sensor.NTC themal Thermistor

2023-08-24Application of NTC thermistor in charging circuit.Human Body Temperature Monitoring Sensor

2022-06-07Hand warmer thermistor selection model

2022-09-05NTC sensor applications.Human Body Sensor

2023-07-03NTC thermosensitive material

2022-11-11NTC temperature probe sensor

2022-12-07Suitable for ultra-low temperature NTC thermistors.Small Human Body Sensor price

2022-08-24

szhaiwang4@hotmail.com

+86-18682200597

sales@szhaiwang.com